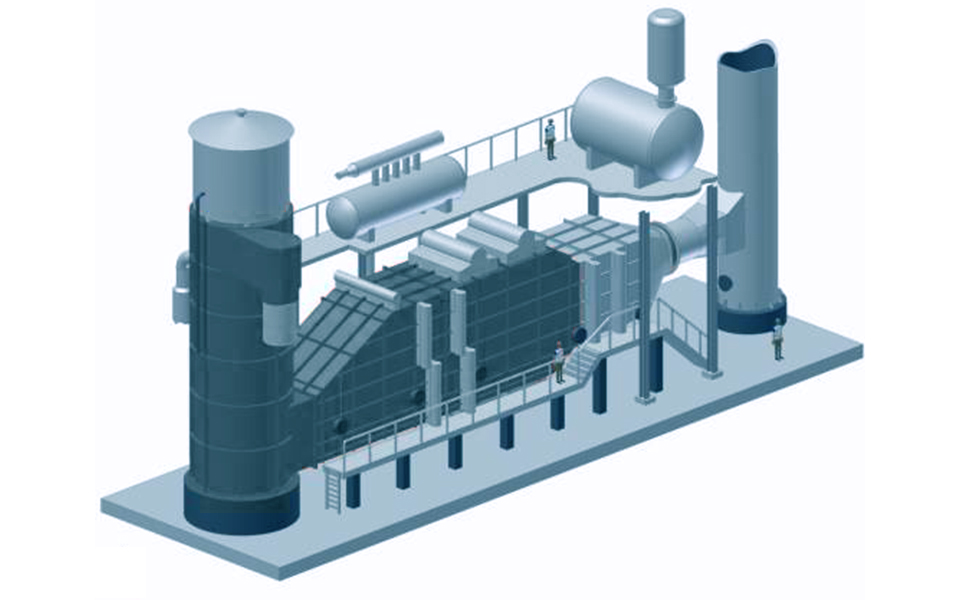

SCHACK® Tailgas Boiler

ECONOMICAL MEET ECOLOGICAL BENEFITS

The tailgas generated during the carbon black production has significant energy potential due to ist combustible element content.

For environmental sustainability, the gas has to be treated in a thermal oxidizer minimizing the quantity of hazardous substances. The recovered energy is used to generate steam and electricity, providing economic advantages to the plant owner.

SCHMIDTSCHE SCHACK’s experience in the combustion of CO gas combined with sophisticated examination methods permit the optimization of the equipment in strict accordance with all CO and NOx emission requirements.

Main Features

Of SCHACK® Tailgas Boiler

The main features of SCHACK® Tailgas Boilers are the long-term and sustainable operation. Additionally, CO2 emission of the carbon black plant is reduced substantially.

A reliable system to meet the high requirements of state-of-the-art carbon black plants in terms of availability, maintainability, efficiency and environmental protection is provided through SCHACK® Tailgas Boilers. Their modular design possibilities meet today’s individual requirements.

Your Benefits

- Energy utilization from combustible elements in tailgas

- Electricity generation creating additional income

- Plant profitability optimization

- CO2 emission reduction

- Reliable and sustainable solution

- Modular design

You are interested in SCHACK® solutions for Carbon black plants and would like to get further information?

Get our epaper on solutions for carbon black plants.

Go for the Original

SCHACK® Solutions for Carbon Black Plants

You are interested in SCHACK® solutions for Carbon Black plants and would like to get further information?

Get our epaper on solutions for Carbon Black Plants.

Get in Touch

You want to learn more?

Please get in touch with our leading expert on SCHACK® Tailgas Boiler.

Jürgen Lauer

Phone: +49-211-4726-120

E-Mail: juergen.lauer@arvos-group.com