SCHMIDTSCHE SCHACK Waste Heat Boiler

Precisely tailored for demanding process requirements

SCHMIDTSCHE SCHACK Waste Heat Boilers use the waste heat formed as a by-product of another process (e.g. within the sulfur recovery (Claus) or sulfuric acid process) and convert it into useful and effective thermal energy. Waste heat boilers contribute to the improvement of thermal efficiency, energy saving as well as environmental protection. The SCHMIDTSCHE SCHACK waste heat boilers are specially designed for tough process conditions appearing within the Claus or sulfuric acid process.

Each of our Waste Heat Boiler is a unique custom-made item. One of the biggest challenges with these processes is to maintain the Waste Heat Boiler gas outlet temperature constant regardless of the load. This can be ensured with the support bypasses on the gas or steam side, which are provided with appropriate control devices.

SCHMIDTSCHE SCHACK unique SCHMIDT’SCHE® and SCHACK® Waste Heat Boilers are individually designed to the process requirements and provide special design features for the various operating conditions and applications.

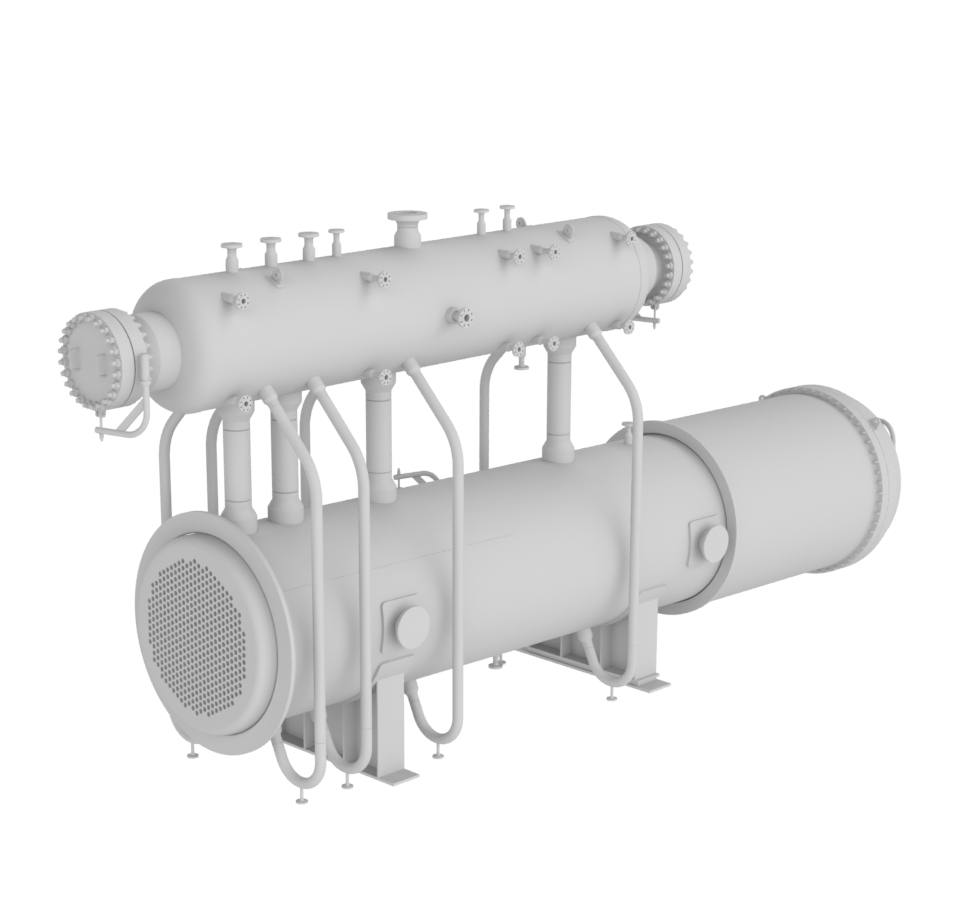

SCHMIDT’SCHE® Waste Heat Boiler Fire Tube-Type

For Sulfur Recovery (Claus) Process

The temperature inside a Claus furnace is often maintained above 1,050 °C (1,922 °F). The SCHMIDT’SCHE® Waste Heat Boiler downstream the combustion furnace cools the hot gases and at the same time recovers valuable energy.

Your Benefits

- Thermal & mechanical design ensures reliable natural water circulation

- Low pressure operation (up to 400 psig)

- Self-cleaning design (similar to FGTT Air Preheater)

- Crevice free weld of tube to tubesheet connection

- Highly resistant against corrosion issues by material selection

- Performance records that far exceed the industry average

In addition, the SCHMIDT'SCHE® Waste Heat Boiler Fire Tube-Type is also applicable for sulfuric acid processes.

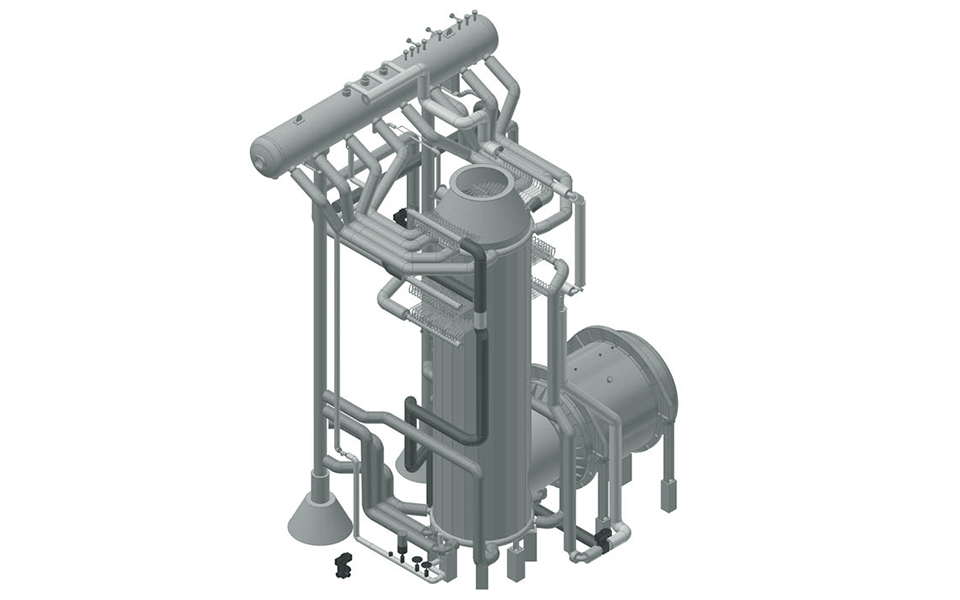

SCHACK® Waste Heat Boiler Water Tube-Type

For the Sulfuric Acid Process

SCHACK® Waste Heat Boiler is a valuable application for the sulfuric acid process. Elemental sulfur is oxidized and then converted to sulfuric acid in a catalytic, exothermic process. Several systems are already successfully in operation worldwide. In the cooling sections that are required, several heat exchangers cool the gases to the required temperatures.

Your Benefits

- Handling temperatures up to 1,600 °C (2,912 °F)

- Fouling can be handled with on-line cleaning

- Higher pressure operation

- Designed to handle hot waste gases in contact with the boiler tubes

- Highly resistant against corrosion issues by material selection

- Performance records that far exceed the industry average

Get in Touch

You want to learn more?

Please get in touch with our leading expert on waste heat boilers.

Jürgen Lauer

Phone: +49-211-4726-120

E-Mail: juergen.lauer@arvos-group.com